Rotary Seals Bring Sweet Success to the Chocolate Industry

Rotary shaft seals, known for their ability to prevent leaks and contamination in industrial mixing, conveying, and processing equipment, are becoming an integral component in all areas of chocolate manufacturing.

Holding and melting tanks, conches, cocoa refiners, sugar screw conveyors, and industrial mixers are all crucial in the chocolate making process. Advanced rotary shaft seals by CinchSeal save manufacturers a staggering amount each year by preventing these machines from leaking valuable chocolate.

Safer, more efficient seals

Efficiency and safety are the cornerstones of modern food processing, and rotary shaft seals deliver on both fronts. Unlike commonly used mechanical seals which are prone to rapid wear and cumbersome maintenance, rotary seals spin seamlessly with the shaft to eliminate friction. Using FDA-approved silicone elastomers, these seals prevent leaks before they happen for a safer, cleaner, and more productive operation.

Before & After

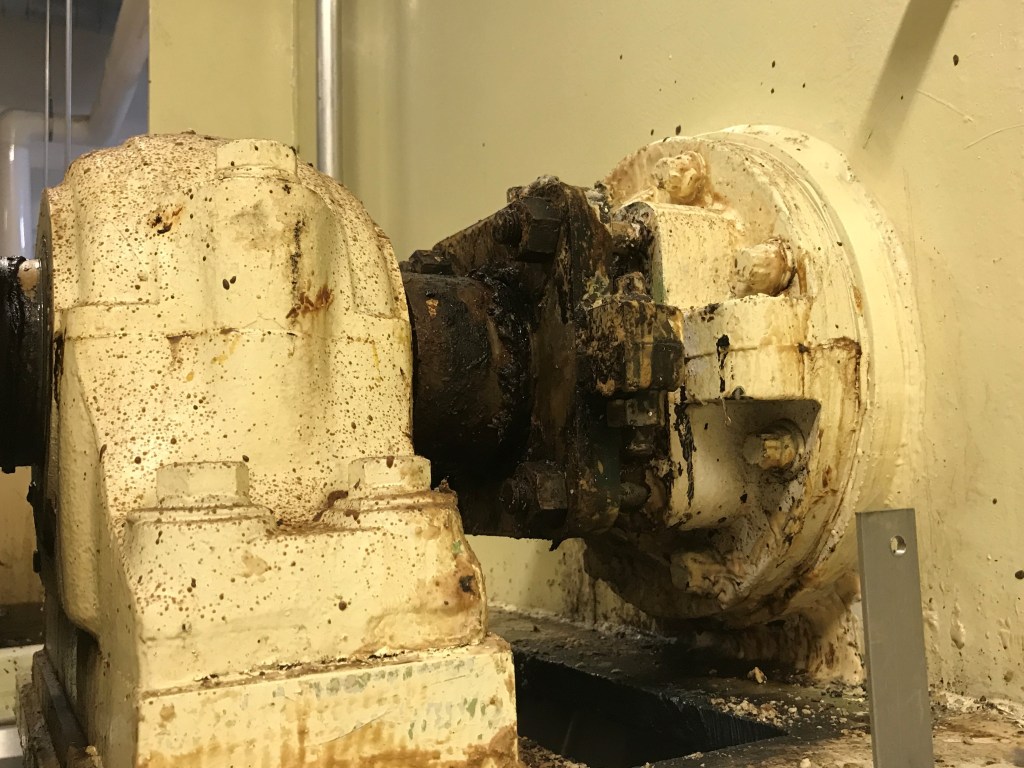

The below photos illustrate the stark difference between chocolate buildup and spillage caused by inefficient mechanical seals, versus the clean, zero-waste result of using rotary shaft seals on the same machines.

How are rotary seals changing the game?

Safety and productivity are built into CinchSeal rotary shaft seals by design. Our seals offer:

- Leak prevention with an FDA-approved silicone elastomer that moves with the shaft, avoiding shaft damage for less maintenance and fewer replacements

- Rotary cups that maintain optimal spacing from stationary faces

- Air purging for enhanced performance

- A large shaft-seal interface that minimizes the risk of contamination

- Streamlined repairs with “split” seals that eliminate the need for laborious housing unbolting

- Easy installation, requiring minimal installation expertise

- Quick seal renewal with repair kits that replace only the elastomer and stator plates

CinchSeal rotary shaft seals have earned the trust of industry regulators, with USDA certification for poultry and dairy, and meeting rigorous FDA standards. This level of endorsement speaks volumes about the reliability and safety of our seals, setting them apart from alternatives like lip seals, O-rings, and mechanical packing.

Why compromise?

As demand for quality chocolate rises and competition intensifies, there’s no room for compromise. Rotary shaft seals by CinchSeal offer unparalleled safety, maximum productivity, and significant cost savings. It’s a recipe for success that chocolate manufacturers can’t afford to overlook.

Innovative & Experienced Rotary Shaft Seal Manufacturers

Since 1994, CinchSeal has been a major manufacturer of rotary shaft seals for screw conveyors, ribbon blenders and all kinds of bulk handling equipment. CinchSeal products serve as replacements and upgrades that make the need for machine replacement less likely.

More information on our industrial seal solutions is available by contacting CinchSeal. Quotes and drawings are guaranteed to be available in 24 hours. Custom engineering usually takes 10 days.